We make plastic, resin and composite plastic/resin mounts for DSLRs.

Although custom digital camera mounts cost quite a bit to make we offer custom parts for your camera.

3D part cutting, printing and molding service.

Depending on the camera and parts needed a model might have to be made in CAD before they can be printed or cut.

Digital Camera Mounts – Materials

PLA: Mounts are strong but a little brittle but they are the cheapest to make.

ABS: Parts are waterproof but a little softer than PLA.

Metal: Parts are quite expensive to make but last a long time.

Other

Composite plastic/resin mounts: They work quite well and fit together really nicely but as they are usually the the most complicated to make they can end up costing the most to produce.

Bake your PLA and have it outperform everything else!

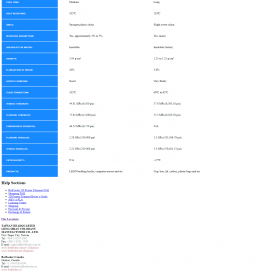

ABS and PLA Comparison Table

External site moved from https://www.botfeeder.ca/abs-vs-pla/

Here is detailed comparison of ABS- and PLA-material.

| ABS | PLA | |

|---|---|---|

OFFICIAL NAME: |

Acrylonitrile butadiene styrene | Polylactic acid or polylactide |

MOLECULAR FORMULA: |

(C8H8·C4H6·C3H3N)n | (C3H4O2)n |

DERIVED FROM: |

Chemical compound: Acrylonitrile, butadiene, and styrene | Renewable resources: Corn starch, tapioca roots, chips, starch, or sugarcane |

ENVIRONMENTAL FRIENDLY: |

No | Yes |

DEGRADABLE: |

No | Yes |

MELTING POINT: |

205ºC | 175ºC |

ROCKWELL HARDNESS: |

R105 to R110 (Harder) | R70 to R90 |

SURFACE QUALITY: |

Fine | Good |

COOL TIME: |

Medium | Long |

HEAT RESISTANT: |

105ºC | 110ªC |

SMELL: |

Stronger plastic odour | Slight sweet odour |

MOISTURE ABSORPTION: |

Yes, approximately 3% to 5% | Yes, minor |

SOLUBILITY IN WATER: |

Insoluble | Insoluble (better) |

DENSITY: |

1.04 g/cm³ | 1.23 to 1.25 g/cm³ |

ELONGATION AT BREAK: |

20% | 3.8% |

ACRYLIC BONDING: |

Good | Very firmly |

GLASS TRANSITION: |

105ºC | 60ºC to 65ºC |

TENSILE STRENGTH: |

44.81 MPa (6,500 psi) | 57.8 MPa (8,383.18 psi) |

FLEXURAL STRENGTH: |

75.84 MPa (11,000 psi) | 55.3 MPa (8,020.58 psi) |

COMPRESSIVE STRENGTH: |

46.54 MPa (6,750 psi) | N/A |

FLEXURAL MODULUS: |

2.28 GPa (330,000 psi) | 2.3 GPa (333,586.79 psi) |

TENSILE MODULUS: |

2.21 GPa (320 000 psi) | 3.3 GPa (478,624.53 psi) |

CRYSTALLINITY: |

N/A | ~37ºC |

PRODUCTS: |

LEGO building bricks, computer parts, etc | Cups, boxes, lids, cutlery, plastic bags, etc |